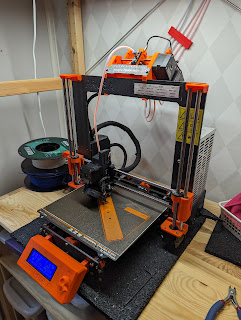

MMU2s --> MMU3 Upgrade Review

I had an early MMU2, which I later upgraded to a MMU2S. This meant I was using an old 2018 version of the MMU PCB and stepper motor set. The MMU3 upgrade kit doesn't include any of these - it is basically just a hardware kit (as in nuts and bolts), a new power supply board (which is probably the actual critical item of the MMU3), and a full set of redesigned and optimized printed parts (which you print yourself from supplied filament). All of this is well documented elsewhere, so I won't say anything here about the actual build other than it was fairly straightforward and easy to follow.

Clownfish initial test print in eSUN PLA+. Model source HERE

The initial test prints were 'out of the box' better than the old MMU2s - but still not perfect. Interventions were still needed - but a large improvement from the MMU2s. The errors were also much easier to deal with as there is now some trouble-shooting text displayed on the printer's LCD.

Errors typically were of two types:

- The FINDA or print head sensor wouldn't recognize the filament change had been successful and reached the head sensor

- During filament retraction, the filament tip would back too far out of the selector, so the selector couldn't grab and load it during the next exchange

FINDA Tuning

To address the FINDA error described above, I adjusted FINDA sensor. The installation manual recommends setting this to to barely turn on when a filament is inserted - however didn't always recognize when a filament was inserted during changes. I adjusted this to barely turn off when a filament was removed - this seemed to increase reliability of filament changes, in particular with flexible filaments. The new method of tuning this sensor with a screw is a big improvement over the MMU2.

After adjusting the FINDA- the only failures seen was from filament retracting too far out of the MMU selector- probably due to the auto-rewind spool holder. I'm also printing TPU using the MMU, which seems to work better than expected as this isn't a supported filament type from PRUSA.

Too much auto-rewind action

I'm using gravity auto-rewind filament spools. These seem to cause intermittent problems by pulling too much filament out of the selector during filament change. I'm planning on switching to a simpler spool holder with no auto-rewind, and just a method to manage the slack created during filament unload. I haven't found an existing design yet that I like, I might just design and build one.