- belt drive extruders seem to be far superior to geared extruders - no backlash, smooth operation, and no wear.

- The 00str00der design didn't seem to be optimum, at least for my installation on a MendelMax 1.5 printer:

- The mounting orientation perpendicular to the X-slides causes considerable flexing of the slide rods during prints, causing the nozzle to move in the "y" direction and thus adding print inaccuracies

- Extruder design doesn't tie stepper mount to structure surrounding hobbed bolt, possibly allowing flex

- Use of rubber discs for springs vs. wound steel springs does not create as much clamping force between the idler bearing and the hobbed bolt, causing filament feed problems

- The slots that provide for belt tensioning don't have enough travel, making installation of the belt difficult.

|

| Photo showing stepper motor hanging over front edge of X-slide rods |

Since I'm trying to slowly increase the print quality and precision of the printer, I decided to re-design the printer to try and address the problems I noticed. I couldn't find Solidworks files of either the 00str00der or any of the Greg's Wade style extruders, I started this design from scratch, using a few of the existing components. (Idler being one)

Main features of this new extruder:

- orients all components directly over X-slide rods to minimize twisting

- long slots for belt tension adjustment and easy belt installation

- super-beefy construction to minimize flex within part during prints

I've uploaded the .stl files and solidworks models to thingiverse, located here.

|

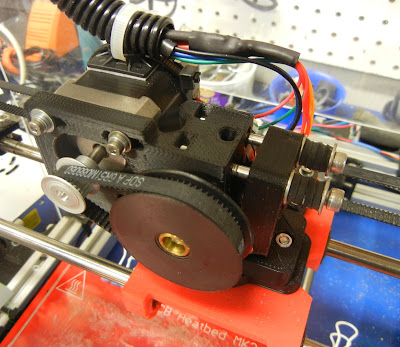

| Belt Drive Extruder, assembled |

|

| Extruder, Mounted |

|

| Note stepper mount is directly attached to extruder body, no gaps |

So far is seems to work well. I did switch the rubber elastomer pucks in the idler tension mechanism for some coil springs. The pucks wouldn't supply consistent pressure on the idler wheel.